Total solutions for commercial

and industrial hanging challenges

and industrial hanging challenges

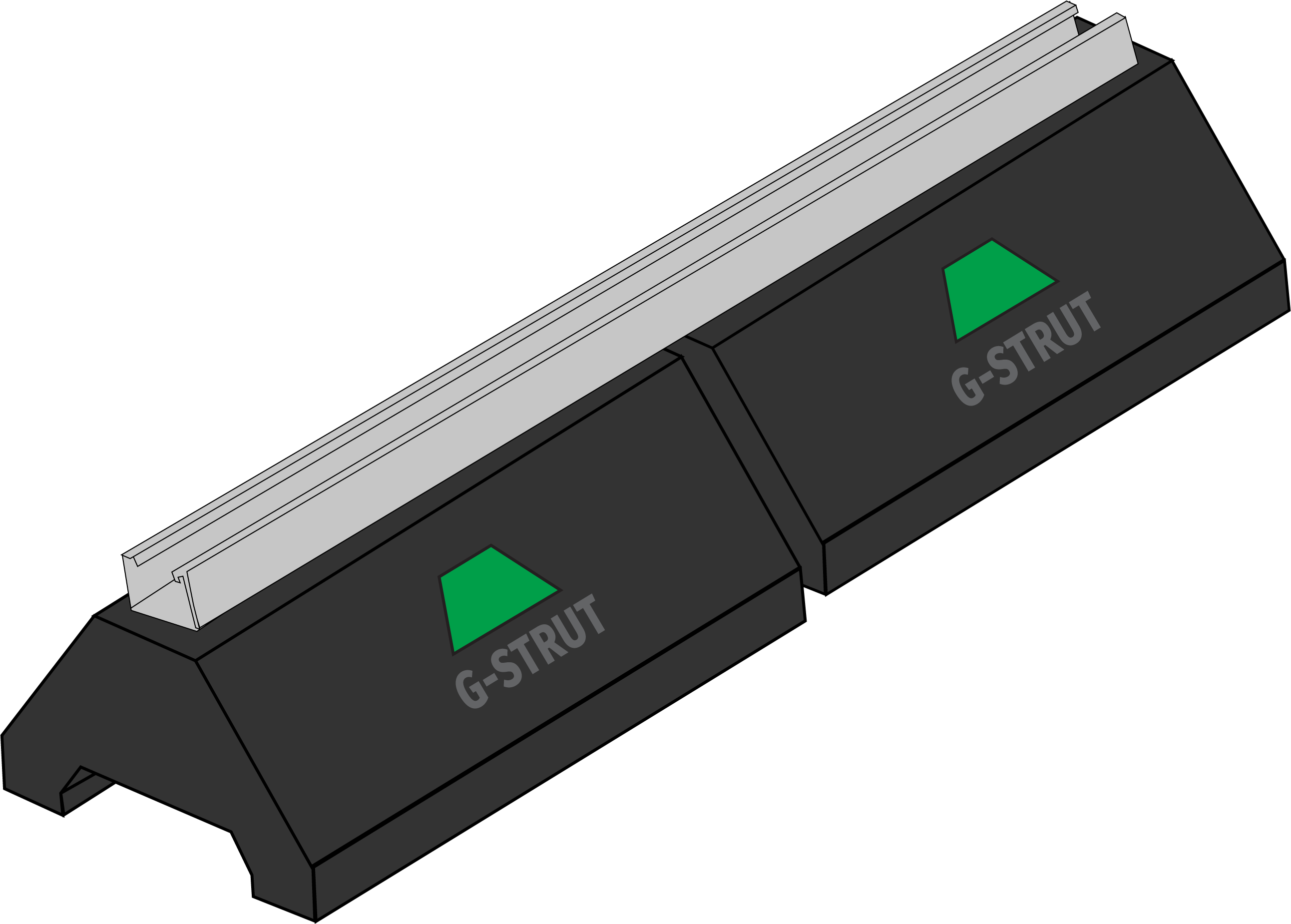

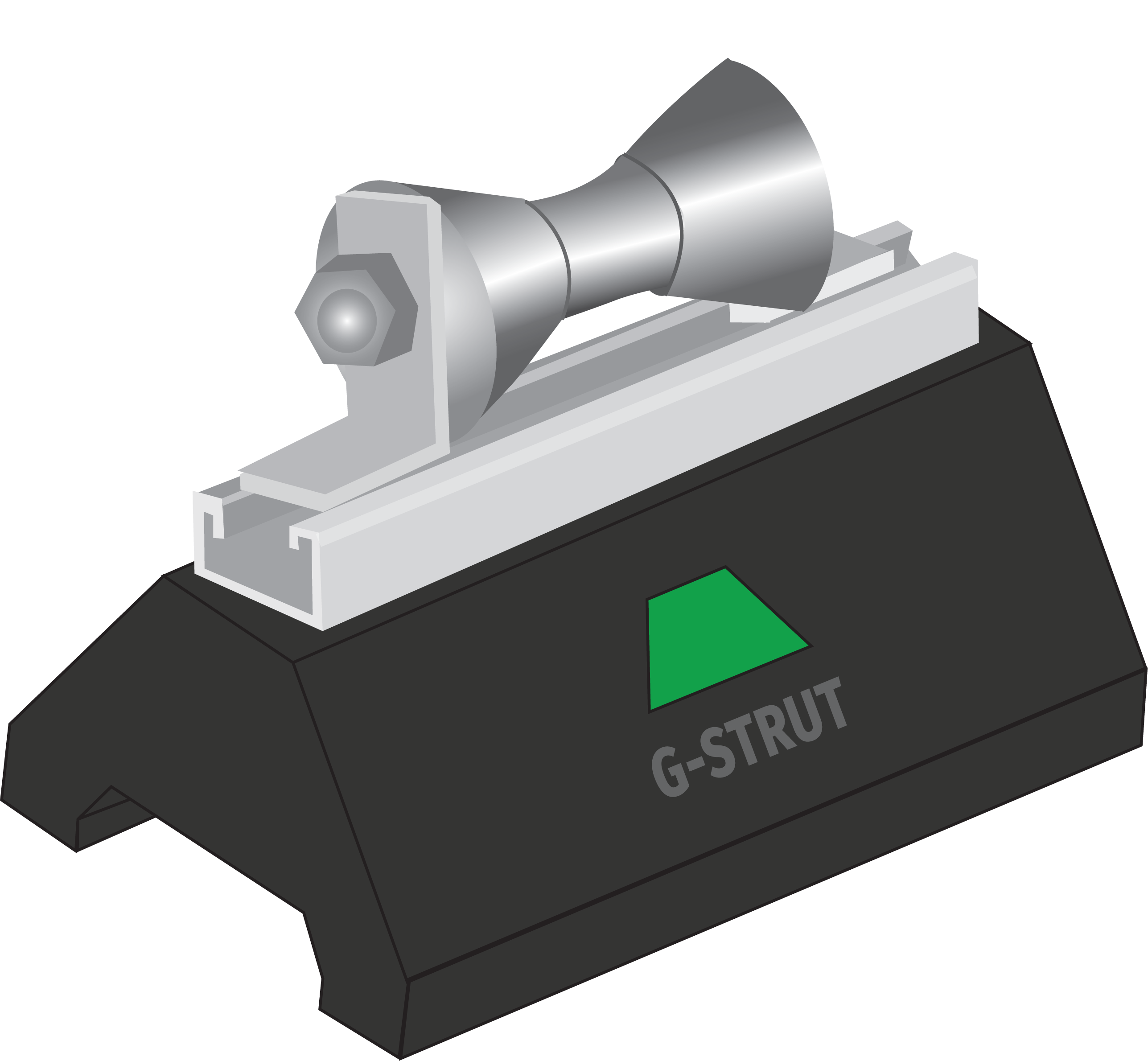

Gregory Strut manufactures close tolerance galvanized, stainless and green G-STRUT® metal framing channels as well as a complete line of strut accessories, fittings, pipe hangers and supports. Whether you’re shopping for a new construction or retrofit project, the combination of G-STRUT® products means unlimited ways to hang, hold and complete the job with flexibility.

Gregory Strut Products

Looking to create a submittal sheet that is customized to your project? Follow these steps:

Visit our product guide.

Click on a product.

Add it to the basket.

When you are finished, click on

the basket in the screen's top

righthand corner and generate a

submittal packet PDF.

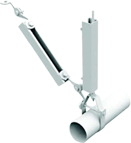

Seismic Brace

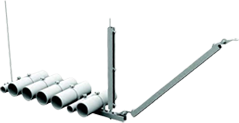

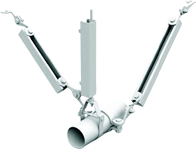

Trapeze with Transverse Brace

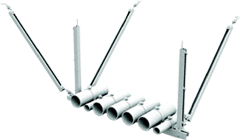

Trapeze with Transverse & Longitudinal Brace

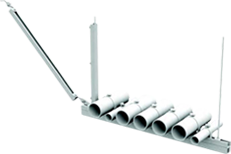

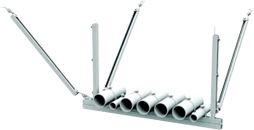

Double Trapeze with Transverse Brace

Double Trapeze with Transverse & Longitudinal Brace

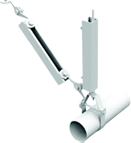

Single Pipe with Transverse Brace

Single Pipe with Transverse & Longitudinal Brace

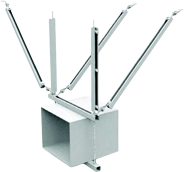

Single Duct with Transverse Brace

Single Duct with Transverse & Longitudinal Brace

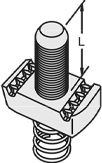

Regular Spring Channel Nuts with Studs

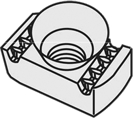

Mini Channel Nuts for Mini Strut

EZ NUTS for all Channels

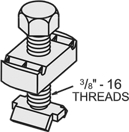

Double Conveyor Adjusting Nut

Seismic Rod Stiffener

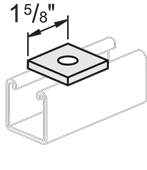

Square Washer

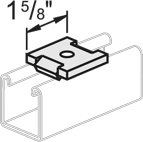

No-turn Square Washer

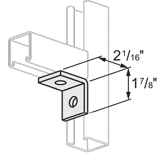

90 Angle Fittings Two-hole Connection Angle

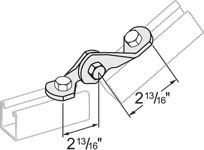

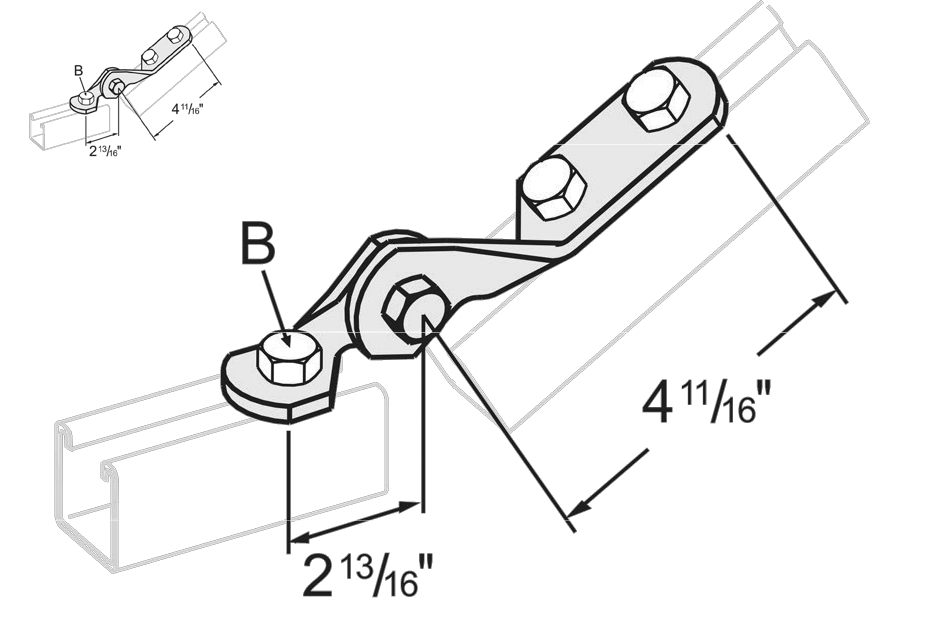

Two-hole Adjustable Hinge

Three-hole Adjustable Hinge

Four-hole Adjustable Hinge

Specs & Submittals

Literature

Tools & Resources

Have a part number that belongs to another vendor?

Use our interactive cross reference tool.

Get started

Contact one of our trusted sales reps to discuss your needs and request product details today.

Get in touch

Group Affiliations