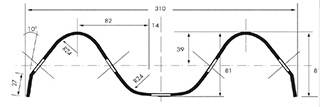

W-Beam Guardrail for Highways

Gregory Highway W-Beam guardrail is produced in standard AASHTO 12' 6" or 25' 0" lengths. In addition to the standard W-beam sizes, custom lengths and custom post-hole spacing are available on request. Gregory W-Beam steel guardrail is offered in 10-gauge or 12-gauge steel and four types of finishes. We also offer pre-curved shapes as part of our commitment to value.

W-Beam Steel Galvanizing Process

We begin with prime steel that matches the requirements for quality, physical properties, and chemistry. A multi-stage cleaning process prepares the metal for galvanizing on our continuous galvanizing line. Production then pierces the steel with holes and/or slots (to either industry standards or W-beam guardrail specifications) and roll-forms it into the W-Beam profile in one continuous process.

Gregory’s continuously galvanized process assures a consistent finish on the W-beam steel guardrails. It also eliminates sharp points and uneven zinc build-up that is typically found in hot-dip galvanized products. While most highway guardrail manufactured by Gregory is supplied in galvanized finish, it is also available in black, painted epoxy coatings, or weathered steel as alternative finishes for aesthetic applications.

W-Beam Guardrail Meets AASHTO Specifications

Gregory W-Beam guardrail is manufactured to AASHTO specifications in M-180 Class A or B, and finish types 1, 2, 3, or 4. Every piece of steel guardrail is stamped with a brand registration that is repeated throughout the entire length of the rail.

Gregory Stamping Code:

- Manufacturer: GH=Gregory highway

- AASHTO Specifications

- Mill Heat Number Code

- Galvanized Lot

- 09 = Week (9th week)

- 07 = Year (2007)

5. Class

- Class A = 12 gauge

- Class B = 10 gauge

6. Type

- Type 1 = Zinc coated 1.8 oz/sq. ft. (550 g/sq. m.) minimum single spot

- Type 2 = Zinc coated 3.6 oz/sq. ft. (550 g/sq. m.) minimum single spot

- Type 3 = Uncoated Steel

- Type 4 = Weathering Steel

PARTNER WITH GREGORY HIGHWAY

When you need complete solutions that are strong, long-lasting, and easy to install, you need to partner with Gregory Highway. As the national leader in highway guardrails and roadside safety, you can rely on us for quick turnarounds, competitive pricing, and responsive service. And we’re proud to say our steel guardrail and highway products are manufactured in the heart of the U.S. Contact us today to get started on your next highway safety project.