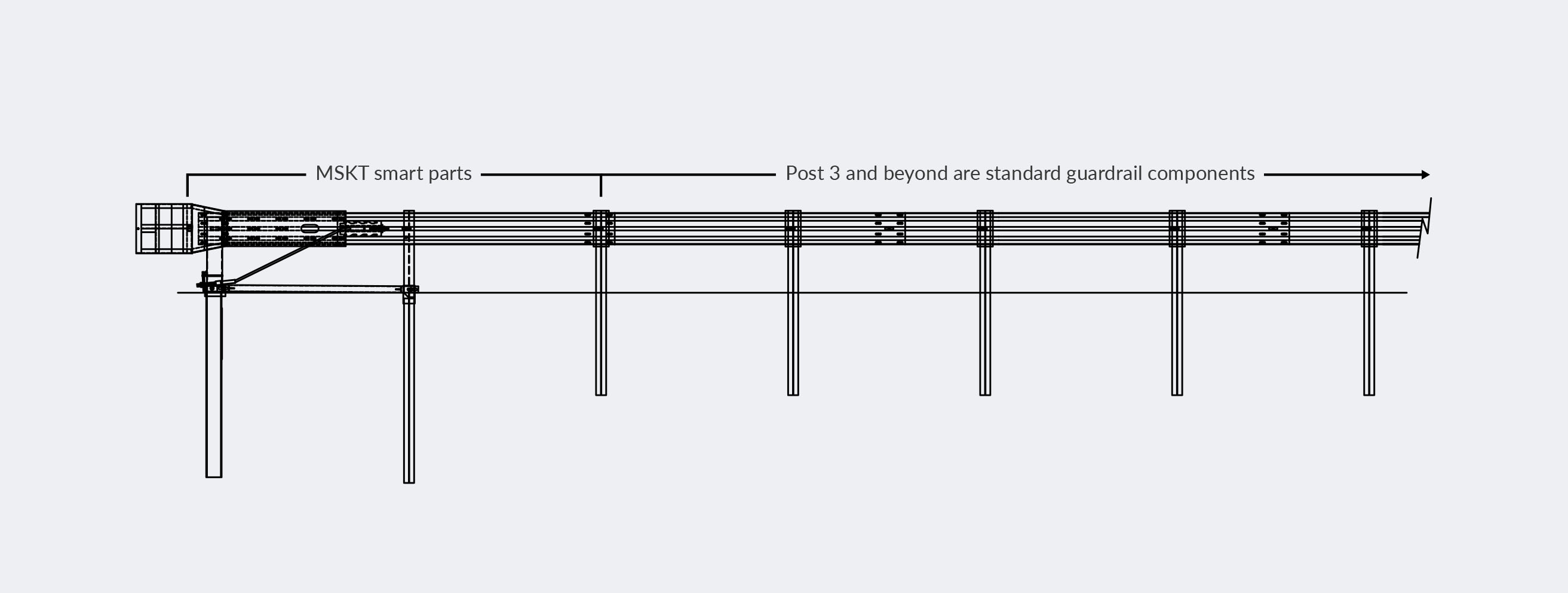

MSKT Guardrail End Terminal – MASH Sequential Kinking Terminal

MSKT Guardrail End Terminal Features

- MASH TL-2 and TL-3 compliant

- Utilizes the same field-proven sequential kinking technology used in the NCHRP 350 SKT

- Energy-absorbing tangent terminal uses proven sequential kinking technology

- Improved impact head and anchorage system

- Length of need point at post 3 is 12’6” downstream

- Easy installation; familiar for work crews

- The same footprint as NCHRP 350 SKT

- Enhances highway safety

Product Specifications

- 50 ft. long with 8 posts spaced at 6’3” centers

- Use with rail heights of 30 to 32 inches

- 25:1 optional flare rate

- 8” or 12” blocks

AASHTO Specifications

Our guardrail is manufactured to AASHTO specifications in M180 Class A or B, and finish types 1, 2, 3, or 4. Every piece of Gregory Highway guardrail is stamped with a brand registration that is repeated throughout the entire length of the rail.

Gregory Stamping Code:

- Manufacturer: GH=Gregory highway

- AASHTO Specifications

- Mill Heat Number Code

- Galvanized Lot

- 01 = Week (1st week)

- 23 = Year (2023)

- Class

- Class A = 12 gauge 0.105in (2.67mm)

- Class B = 10 gauge 0.135in (3.43mm)

- Type

- Type 1 = Zinc coated 1.8 oz/sq. ft. (550 g/sq. m.) minimum single spot

- Type 2 = Zinc coated 3.6 oz/sq. ft. (1,100 g/sq. m.) minimum single spot

- Type 3 = Uncoated Steel

- Type 4 = Weathering Steel

PARTNER WITH GREGORY HIGHWAY

When you need complete solutions that are strong, long-lasting, and easy to install, you need to partner with Gregory Highway. As the national leader in highway guardrails and roadside safety, you can rely on us for quick turnarounds, competitive pricing, and responsive service. And we’re proud to say our steel guardrail and highway products are manufactured in the heart of the U.S. Contact us today to get started on your next highway safety project.