Gregory Guardrail and Highway Safety Product Resources

Explore our industry-leading highway solutions

Review our highway resources to learn more about our galvanized highway guardrails, end treatments, high-tension cable barrier systems and more. It is our mission to answer your questions, solve your problems and support your business needs any way we can. Don’t hesitate to contact the Gregory Highway team if you want to know more about our people, products processes or how we can help.

Gregory Highway Safety Products Catalog

Explore our full capabilities or contact us now to request a quote.

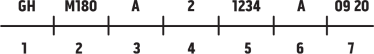

Stamping Codes

- Manufacturer (GH = Gregory Highway)

- AASHTO Specifications

- Class: Class A = 12 ga, Class B = 10 ga

- Type:

- Type 1 = Zinc coated 1.8 oz/ft2 (550 g/m2) min single spot

- Type 2 = Zinc coated 3.6 oz/ft2 (1100 g/m2) min single spot

- Type 3 = Uncoated Steel

- Type 4 = Weathering Steel

- Mill Heat Number

- Operator identification (A-Z)

- Galvanized Lot: 09 = Week (9th week), 17 = Year (2017)

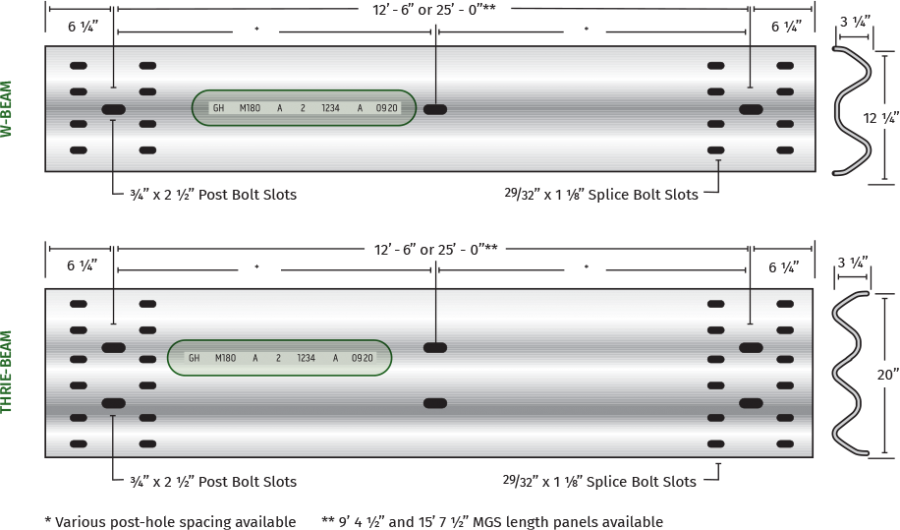

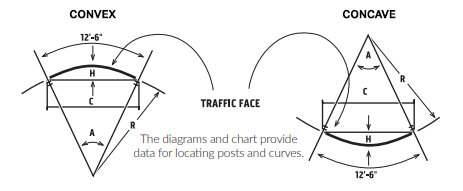

Convex and Concave Curved Guardrail Panels

Guardrail sections to be installed on curves with a radius of 5 ft. to 150 ft. can be curved in our fabricating facilities. Terms convex or concave refer to the inward or outward curve relative to the traffic face of the guardrail.

Finding the radius for a curved guardrail:

Starting at the last post in the straight run (point A), lay cloth tape along the path that the curved guardrail will follow.

Mark off two points along the curved cloth tape: one at 6 ft. 3 in. (point B), and the second at 12 ft. 6 in. (point C).

Pull string directly from starting point (point A) to the second mark-off point (point C).

Measure from the first markoff point (point B) over to the midpoint of the taut string. This measurement (D) is the rise.

Check the chart to find the radius (R), given the rise (D). Example: a rise of 3 7/8 in. would result in a radius of 60 ft.

| RADII | ANGLE | CHORD | HEIGHT / RISE |

|---|---|---|---|

| 5 | 143˚ 14’ | 9' 5-7/8" | 3’ 5” |

| 10 | 71˚ 37’ | 11’ 8-3/8” | 1’ 10-3/4” |

| 15 | 47˚ 45’ | 12’ 1-3/4” | 1’ 3-3/8” |

| 20 | 35˚ 49’ | 12’ 3-5/8” | 11-5/8” |

| 25 | 28˚ 39’ | 12’ 4-1/2” | 9-3/8” |

| 30 | 23˚ 52’ | 12’ 4-7/8” | 7-3/4” |

| 35 | 20˚ 28’ | 12’ 5-1/8” | 6-5/8” |

| 40 | 17˚ 53’ | 12’ 5-3/8” | 5-7/8” |

| 45 | 15˚ 55’ | 12’ 5-1/2” | 5-1/4” |

| 50 | 14˚ 19’ | 12’ 5-5/8” | 4-5/8” |

| 55 | 13˚ 01’ | 12’ 5-5/8” | 4-1/4” |

| 60 | 11˚ 56’ | 12’ 5-3/4” | 3-7/8” |

| 65 | 11˚ 01’ | 12’ 5-3/4” | 3-5/8” |

| 70 | 10˚ 14’ | 12’ 5-3/4” | 3-3/8” |

| 75 | 9˚ 33’ | 12’ 5-3/4” | 3-1/8” |

| 80 | 8˚ 57’ | 12’ 5-7/8” | 3” |

| 85 | 8˚ 26’ | 12’ 5-7/8” | 2-3/4” |

| 90 | 7˚ 58’ | 12’ 5-7/8” | 2-5/8” |

| 95 | 7˚ 32’ | 12’ 5-7/8” | 2-1/2” |

| 100 | 7˚ 10’ | 12’ 5-7/8” | 2-3/8” |

| 110 | 6˚ 31’ | 12’ 5-7/8” | 2-1/8” |

| 120 | 5˚ 58’ | 12’ 6” | 2” |

| 130 | 5˚ 31’ | 12’ 6” | 1-3/4” |

| 140 | 5˚ 07’ | 12’ 6” | 1-5/8” |

| 150 | 4˚ 47’ | 12’ 6” | 1-1/2” |

Hardware Drawings

End Section Drawings

Post Drawings

Transition Drawings

Sell Sheet

The Guardian 5 (G5) serves as a softer, safer alternative to concrete. It functions as a median and longitudinal barrier that safely redirects a fully loaded 80,000-lb. vehicle. It is utilized in situations that feature reduced post spacing, higher impact speeds and curbing.

Drawings

The MFLEAT is a MASH TL-3 compliant, energy absorbing flared terminal end that safely disperses crash energy during head-on collisions. Functioning like a guardrail, it effectively redirects vehicles to optimize safety.

Sell Sheet

Acceptance Letters

Manual

The MSKT is an energy absorbing kinking terminal that functions like a guardrail and safely redirects vehicles. When there is an impact, the MSKT head slides over the W-Beam, kinking the terminal and redirecting vehicles safely.

Sell Sheet

Drawings

On impact, the cables acquire lateral resistance and are held in place by the end anchors to safely redirect vehicles. Made in the U.S., these cables are used in medians and embankment slopes where forceful collisions are common.

Sell Sheet

Acceptance Letters

Reports

Manuals

The TTMA-220 is designed for mobile and stationary work zones, protecting valuable assets in the event of a work zone intrusion. It is constructed from galvanized steel and built for versatility.

Sell Sheet

Acceptance Letters

Specifications

Sell Sheet

The SB Barrier is designed for roadside or median applications. It converts crash energy into rotational energy when a vehicle comes into contact. It helps to soften vehicle image, redirect vehicles and improves roadside visibility.