Comparing Manufactured-to-Length Custom Strut Solutions Vs. Field Cuts

Efficiency, precision, and quality – these are the guiding principles that help you deliver superior results to your customers. You know how critical quality strut channel can be for your projects – but did you know that you could be saving time and money with custom strut solutions?

Cut-to-length strut is great for making changes on the fly, but if time is money for you as it is for other contractors and distributors, you could be working a lot more efficiently. Manufactured-to-length strut arrives at your site pre-cut, pre-bundled, and ready to go. It’s a great way to stretch your budget and conserve labor for where it’s most effective.

Learn about the difference between manufactured-to-length and cut-to-length strut, and how custom strut solutions can save time and money by reducing complexity on large-scale projects.

Cut-to-Length Strut

You’re probably familiar with standard-sized framing channel, sold in 10’ and 20’ sections.

It has a wide array of uses for contractors, technicians, and commercial builders. But while framing channel is almost infinitely adaptable to your needs (especially if you use one of Gregory Strut’s specialized strut products) there are times when cutting strut channel in the field can pose some limitations.

For one, it requires setup of a cutting station for workers to cut as well as debur lengths of strut. It also requires labor time to measure, cut, debur, and place. While this is fine for some projects, other projects with tighter timelines or budgets could benefit from efficiency improvements.

Manufactured-to-Length Strut

Unlike cut-to-length strut, manufactured-to-length strut arrives at your facility or job site already cut perfectly to your specifications. The precision manufacturing process means factory-cut strut channel is the right length, every time – no waste or scrap.

And when you rely on Gregory Strut’s superior quality control, you know that you’re getting the exact measurements, close tolerances and finely deburred edges you need to keep your workers safe and your installation moving quickly.

Plus, Gregory Strut’s manufactured-to-length strut channel is delivered in labeled, pre-cut bundles for easy identification.

Key Differences

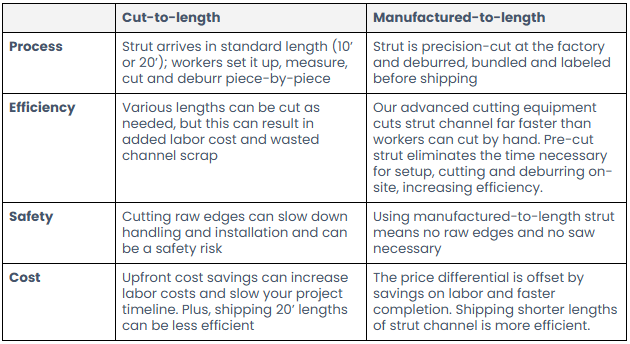

To understand the key differences between using cut-to-length vs. manufactured-to-length strut, consider how each type varies in cutting, shipping, and installation.

Which Should You Choose?

Which option to choose will depend on factors including your project, scope, budget, and timeline.

You might prefer to choose cut-to-length strut if:

- You’re working on a small-scale, one-off or residential project

- You don’t need a large volume of strut channel

- You’re installing a basic structure where close tolerances aren’t as urgent

- You’re performing last-minute repairs or changes

- You expect to require a number of modifications in the field

- Your priority is the upfront cost and not long-term efficiency

On the other hand, manufactured-to-length strut channel is right for applications such as:

- Large-scale commercial and industrial installations

- Projects with numerous identical elements

- Installations requiring tight tolerances and precise measurements

- Areas or sites where cutting channel would be difficult or cumbersome

- Projects where field cuts and modifications could jeopardize structural integrity

The Gregory Strut Advantage

Gregory Strut offers G-Strut® Channel in both standard lengths of 10’ and 20’ as well as precision-cut, manufactured-to-length channel in virtually any size between 6” and 24’.

Our continuous cold-roll-formed steel channel is interchangeable with standard 5/8” metal framing channel systems. It is available in six basic styles, two gauges (12 and 14) and 10 finishes/materials, including pre-galvanized, hot-dipped galvanized, electro-galvanized, galvannealed, powder-coated, PVC coated and yellow zinc.

G-Strut channel, fittings and accessories are made in the USA and conform to industry standards for metal framing including ASTM 1011, ASTM 653 and ASTM 123 (dependent on finish).

If you’re ready to boost efficiency, streamline your next metal framing project with manufactured-to-length G-Strut channel from Gregory Strut. Request a quote or talk to a sales rep today.